Creaform HandySCAN 3D 300

Creaform HandySCAN 3D 300, the most efficient way to reverse engineer and design. TheCreaform HandySCAN 3D 300 is a reliable tool for engineer and design

CreaForm 3D Laser Scanners

CreaForm

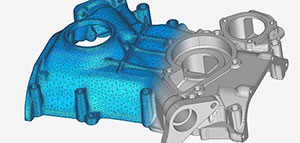

Creaform HandySCAN 3D available in 2 versions, the Creaform HandySCAN 300 and Creaform HandySCAN 700. The Creaform HandySCAN 300 offers the same accuracy as the previous EXAscan system. Uses the laser triangulation technology to 3D scan a wide variety of mechanical parts, mockups and prototypes. The Creaform HandySCAN 300 is suited for various uses cases such as reverse engineering, all steps of design and manufacturing processes, museology heritage preservation, restoration, digital archiving and entertainment. Delivered with the VXelements software suite for 3D scanning and optimizing the 3D files.

Features

- 25 times faster than the previous generation

- 40% more accurate

- Improved ergonomy:

- 35% lighter

- 50% smaller

- Greater freedom of movement

- Multi-function buttons for easier interaction with the software

Truaccuracy

- Metrology-grade measurements: accuracy of up to 0.030 mm (0.0012 in.), resolution of up to 0.050 mm (0.002 in.), high repeatability and traceable certificate.

- Accuracy in real-life conditions: regardless of environment conditions, part set-up or user.

- No rigid setup required: optical reflectors are used to create a reference system that is “locked” to the part itself, so users can move the object any way they want during scanning sessions (dynamic referencing). Changes in surrounding environment have no impact on data acquisition quality or accuracy.

- Self-positioning: the HandySCAN 3D scanner is a data acquisition system and its own positioning system. This means that no external tracking or positioning devices is required. It uses triangulation to determine its relative position to the part in real time.

- Reliable: consistent and repeatable results across all work conditions or environments.

- On-demand user calibration: the scanner can be calibrated as often as necessary (day-to-day basis or before each new scanning session). Calibration takes about 2 minutes and guarantees optimal operation.

Truportability

- Stand-alone device: there is no need for an external positioning system, arms, tripod or fixture.

- On-the-go scanning: you can take it from place to place or use it in-house or on site.

- Lightweight: weights under 1 kg.

- Small: Fits into a case the size of a carry-on.

- Easy access to confined spaces: thanks to its small size and flexible stand-off distance.

Speed

- Fastest 3D scanner on the market: 25 times faster than the previous generation.

- Highest measurement rate among all laser scanners: 480,000 measures/s.

- Automatic mesh output: ready-to-use files, right as you complete acquisition.

- Quick workflow integration: usable scan files can be imported into RE/CAD software without post-processing

Trusimplicity

- User-friendly: very short learning curve, regardless of the user’s experience level.

- Quick set-up: up and running in less than 2 minutes.

- Direct mesh output: no complicated alignment or point cloud processing.

- Real-time visualization: look at the computer screen to see what you are doing and what is left to be done.

- Versatile: virtually limitless 3D scanning – no matter the part size, complexity, material or color.

HandySCAN 3D 300 Technical Spesification

- Accuracy: Up to 0.040 mm (0.0016 in.)

- Volumetric accuracy*: 0.020 mm + 0.100 mm/m(0.0008 in. + 0.0012 in./ft)

- Volumetric accuracy (with maxshot 3D)*: 0.020 mm + 0.025 mm/m (0.0008 in. + 0.0003 in./ft)

- Resolution: 0.100 mm (0.0039 in.)

- Measurement rate: 205,000 measurements/s

- Light source: 3 laser crosses

- Laser class: 2M (eye-safe)

- Scanning area: 225 x 250 mm (8.8 x 9.8 in.)

- Stand-off distance: 300 mm (11.8 in.)

- Depth of field: 250 mm (9.8 in.)

- Part size range: (recommended) 0.1 – 4 m (0.3 – 13 ft)

- Software: VXelements

- Output formats: .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr

- Compatible software: 3D Systems (Geomagic® Solutions), InnovMetric Software (PolyWorks), Dassault (CATIA V5 and SolidWorks), PTC (Pro/ENGINEER), Siemens (NX and Solid Edge), Autodesk (Inventor, Alias, 3ds Max, Maya, Softimage).

- Weight: 0.85 kg (1.9 lbs.)

- Dimensions: 77 x 122 x 294 mm (3.0 x 4.8 x 11.6 in.)

- Connection standard: 1 X USB 3.0

- Operating temperature range: 5-40 °C (41-104 °F)

HandySCAN 3D 300 Application

The HandySCAN 3D scanners: your best ally at all stages of your product lifecycle management

Requirements and spesifications

Requirements and spesifications

- Competitive product analysis

- Measurement of product environment or connecting/Surrounding parts

- Measurement of existing parts for aftermarket or custom equipment

Concept Design

Concept Design

- Clay model measurement/Reverse engineering

- Models and mock-ups measurement/Reverse engineering

- Styling and aesthetics

Concept Prototyping

- Integration of prototype modifications into CAD file

- Form study, proof-of-concept prototypes

- Ergonomy prototypes

DESIGN

CAD Design

CAD Design

- 3D scan-to-CAD

- Reverse engineering (extracting design-intent)

- Packaging design

Prototyping

Prototyping

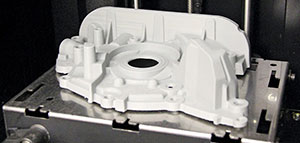

- Rapid prototyping/Manufacturing

- Integration of prototype modifications into CAD file

- Prototype inspection

Testing, Simulation and Analysis

Testing, Simulation and Analysis

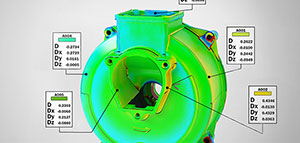

- Finite element analysis (FEA)

- Interference analysis

- Deformation, geometry analysis

MANUFACTURING

Tooling Design

Tooling Design

- Reverse engineering of dies, molds, fixtures, jigs and patterns

- Update of CAD file to reflect as-built tooling measurements

- Tooling validation/Inspection

Assembly/Production

Assembly/Production

- Virtual assembly

- Tool/Robot path programming

- Part assessment before machining

Quality control

Quality control

- First article inspection (FAI)

- Part-to-CAD inspection

- Supplier quality inspection

SERVICING

Documentation

Documentation

- As-built documentation of parts/Tooling

- Marketing presentations, 3D training systems, serious gaming

- Digital archiving

Maintenance, repair and overhaul (MRO)

Maintenance, repair and overhaul (MRO)

- Wear and tear analysis

- Custom repairs/?Modification

- As-built documentation of parts/Tooling before maintenance

Replacement/Recycling

Replacement/Recycling

- Reverse engineering for developing replacement /Restoration parts

- Planning of complex assemblies disassembly/Dismantling

OTHER APPLICATION

- Museology

- Heritage preservation

- Restoration

- Digital archiving

- 3D scanning for research

- Analysis and publishing

- Multimedia

- entertainment

- Computer graphics and special effects.

Software

VXELEMENTS: CREAFORM’S 3D SOFTWARE PLATFORM

The HandySCAN 3D scanners come with VXelements, a fully integrated 3D software platform that powers our entire fleet of 3D scanning and measurement technologies. It gathers all the essential elements and tools into a user-friendly, simplified and sleek working environment. Its real-time visualization provides a simple, enjoyable scanning experience. An optimized scan file is automatically created and available upon completion of

the data acquisition step, which contributes to greatly shorten your part inspection or design process.

VXSCAN: SCAN SOFTWARE MODULE

VXscan is entirely dedicated to the acquisition and optimization of 3D scanning data. It delivers high performance for that specific task, yet it is simple and user-friendly enough to suit any user's experience level.

- User-friendly interface: VXelements was designed to simplify the whole scanning process to its essential core, through a powerful and simple process.

- Surface optimization algorithm: avoids the creation of multiple scan layers and ensures a more accurate mesh without any post-treatment;

- Direct mesh output: an optimized mesh can be exported in all standard formats, right as you complete acquisition. No complicated alignment or point cloud processing needed;

- No limitation to the scan resolution: you simply need to input a resolution value, independent from the size of the scanned object. Resolution can be changed at any time before/after the scan;

- Real-time visualization: the user can view the 3D surface as the object is being scanned;

- Scan results enhancement: hole filling, smart decimation, boundary filters, etc.

Industries

Aerospace, Automotive / Transport, Consumer Products, Heavy Industries, Manufacturing, Research and Education, Power Generation and Others

Aerospace, Automotive / Transport, Consumer Products, Heavy Industries, Manufacturing, Research and Education, Power Generation and Others

Download